Streamlining Optical Fibre Production with the Advanced Optical Fibre Diameter Analyser

Streamlining Optical Fibre Production with the Advanced Optical Fibre Diameter Analyser

Blog Article

Recognizing the Functionality of an Optical Fibre Diameter Analyser in Modern Manufacturing

The optical Fibre Diameter analyser offers as a critical tool in modern manufacturing, providing exact, non-contact dimensions that are essential for maintaining rigid sector criteria. By leveraging advanced laser technology, these analysers not only guarantee very little signal loss yet also enhance the general efficiency of optical fibres.

Significance of Optical Fibre Measurement

In contemporary production, the measurement of optical Fibre Diameter is critical for making sure the efficiency and integrity of Fibre optic systems. Exact Diameter measurement straight influences optical performance, as variants can cause increased signal loss, minimized transmission capacity, and decreased total performance. The optical buildings, including light transmission and signal stability, are very conscious the Fibre's Diameter, requiring exact control throughout production.

Moreover, standardization in Fibre Diameter is essential for compatibility and interoperability within varied telecoms networks. As these networks broaden internationally, preserving harmony in Fibre qualities advertises seamless integration across various elements and systems. Additionally, adhering to industry criteria worrying Diameter tolerances is vital for producers to satisfy regulatory needs and consumer expectations.

Spending in sophisticated dimension innovations not only enhances producing efficiency however additionally supports quality control processes, making it possible for producers to recognize problems early in production. This aggressive method decreases waste and ensures that the end products fulfill stringent performance requirements. Consequently, the significance of optical Fibre dimension can not be overemphasized, as it offers as a foundation for top quality, reputable Fibre optic systems, which are important to contemporary interaction infrastructure.

Exactly How Diameter Analysers Work

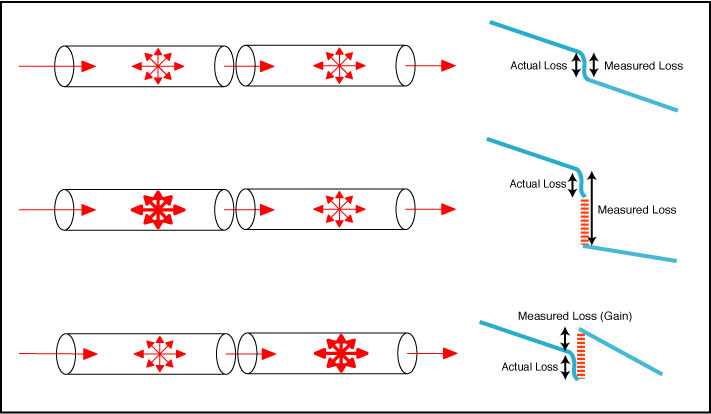

The core procedure depends on the concept of light scattering and representation. As the laser light beam strikes the Fibre, variations in Diameter reason modifications in the light's intensity and wavelength (optical fibre diameter analyser). This information is processed in real-time utilizing innovative algorithms that equate the optical signals into accurate Diameter measurements

In addition, lots of Diameter analysers are geared up with multiple dimension factors along the Fibre, allowing for a detailed evaluation of Diameter consistency. The application of such innovation substantially enhances quality control in production, guaranteeing that optical fibers are generated to specific requirements for optimum efficiency in their designated applications.

Trick Functions to Take Into Consideration

When picking an optical Fibre Diameter analyser, several vital attributes require careful consideration to ensure optimum efficiency and reliability. Measurement accuracy is vital; the analyser needs to provide exact Diameter readings, commonly in micrometers, to fulfill strict manufacturing specs. Additionally, a vast dimension array boosts adaptability, suiting numerous Fibre kinds and densities.

One more crucial attribute is the analyser's rate. Rapid measurement abilities allow for boosted throughput, crucial in high-volume manufacturing environments. Real-time data processing and responses capacities make it possible for instant adjustments, boosting high quality control.

Interface and software program compatibility are also substantial considerations. A straightforward user interface see this page enhances procedure, while robust software assistance facilitates information evaluation and integration with existing manufacturing systems. The capacity to export data in various layouts can enhance coverage and compliance efforts.

Furthermore, longevity and maintenance requirements need to be evaluated. An analyser built from premium products will certainly withstand the rigours of a manufacturing atmosphere, while simplicity of upkeep makes certain longevity and reduces downtime. Finally, consider the level of technological support and training supplied by the supplier, as this can dramatically affect the reliable use the analyser in manufacturing setups.

Benefits in Manufacturing Performance

Enhancing production efficiency hinges on the integration of innovative innovations, such as optical Fibre Diameter analysers. These instruments play a critical role in making sure that optical fibers fulfill rigid top quality standards, which is important for optimum efficiency in different applications - optical fibre diameter analyser. By supplying real-time dimensions of Fibre Diameter, producers can quickly identify and remedy inconsistencies from defined resistances, consequently minimizing waste and decreasing the danger of defective products

In addition, the very early discovery of potential concerns causes lowered downtime and upkeep costs, consequently enhancing resource allotment. Ultimately, the efficiency gets realized with the use of optical Fibre Diameter analysers add to a more competitive production atmosphere, making certain that companies can supply top quality items while maintaining cost-effectiveness and responsiveness to market demands.

Applications Across Industries

The convenience of optical Fibre Diameter analysers prolongs beyond manufacturing performance, discovering applications throughout numerous sectors that depend on optical Fibre innovation. In telecoms, these analysers are crucial for guaranteeing the optimum performance of Fibre optic cords, straight impacting information transmission prices and network integrity. visit here By precisely measuring Fibre sizes, drivers can decrease signal loss and enhance overall interaction top quality.

The clinical sector additionally benefits significantly from these gadgets, specifically in the development of endoscopic devices and laser therapies. Exact Diameter measurements are vital for developing effective optical fibers that are made use of in minimally intrusive procedures, enhancing person you could try here results through boosted imaging and therapy capabilities.

In aerospace, the analysers play a vital role in the manufacturing of lightweight, high-strength materials, where Fibre optics are integrated into structural elements for tracking and diagnostics. Additionally, the vehicle sector uses these tools to make certain the integrity of Fibre optic sensing units that enhance security and efficiency functions in cars.

Final Thought

In verdict, the optical Fibre Diameter analyser is important for modern-day production, making certain exact dimensions that promote industry requirements. The diverse applications across numerous sectors highlight the analyser's relevance in promoting constant improvement and data-driven decision-making within the production industry.

In modern manufacturing, the measurement of optical Fibre Diameter is crucial for guaranteeing the performance and integrity of Fibre optic systems. The relevance of optical Fibre measurement can not be overstated, as it serves as a foundation for high-quality, trusted Fibre optic systems, which are important to modern communication infrastructure.

Diameter analysers employ sophisticated optical technologies to precisely gauge the Diameter of optical fibers.Furthermore, numerous Diameter analysers are equipped with several measurement points along the Fibre, allowing for a thorough assessment of Diameter uniformity.The convenience of optical Fibre Diameter analysers expands beyond making performance, discovering applications throughout various sectors that rely on optical Fibre technology.

Report this page